Anchor Tool Self Drilling Anchor Bolt Threraded Bar Anchor Rod

Products Description

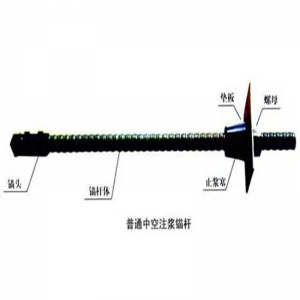

Self-Drilling Anchor Tools: The self-drilling hollow bar anchor system consists of a hollow threaded bar with an attached drill bit that can perform drilling, anchoring and grouting in a single operation. The hollow bar allows air and water to freely pass through the bar during drilling to remove debris and then allow grout to be injected immediately after drilling is completed. Grout fills the hollow bar and completely covers the entire bolt. Couplings can be used to join hollow bars and extend the bolt length while nuts and plates are used to provide the required tension.

| Anchor Rods | |

| R25N, R32N, R32S, R38N | |

| R51L, R51N | |

| T76N, T76S | |

|

Drill Bits |

|

| 42, 51, 76, 90, 115mm | |

|

85/100/115mm |

|

|

130mm |

|

|

|

Anchor Coupling Sleeves |

| Anchor Nuts | |

| Anchor Plates |

PRODUCT SPECIFICATION

Anchor Rods:

|

Types |

Outer Diameter |

Average Internal Diameter |

Effective External Diameter |

|

mm |

mm |

mm |

|

R25N |

25 |

14 |

23 |

|

R32N |

32 |

18.5 |

29.1 |

|

R32S |

32 |

15 |

29.1 |

|

R38N |

38 |

19 |

35.7 |

|

R51L |

51 |

36 |

47.8 |

|

R51N |

51 |

33 |

47.8 |

|

T76N |

76 |

51 |

76 |

|

T76S |

76 |

45 |

76 |

|

Length: 1m, 1.5m, 2m, 2.5m, 3m, 3.5m, 4m, 4.5m, 5m, 5.5m, 6m |

|||

Drill Bits:

|

Anchor Type |

Bit Size |

Front Design |

|

R25N |

R25-42mm, R25-51mm |

Cast Cross Bits, Steel Cross Bits, Steel 3-Cutter Bits, TC Cross Bits, TC 3-Cutter Bits, Steel Arched Bits, TC Arched Bits, Steel Button Bits, TC Button Bits |

|

R32N & R32S |

R32-51mm, R32-76mm |

|

|

R38N |

R38-76mm, R38-90mm, R38-115mm |

|

|

R51L & R51N |

R51-85mm, R51-100mm, R51-115mm |

|

|

T76N & T76S |

T76-130mm |

Anchor Coupling Sleeves, Anchor Nuts & Anchor Plates:

|

Thread Type |

Anchor Couplings |

Anchor Nut |

Anchor Plates (Square & Round) |

|||

|

Diameter |

Length |

Hex. Diameter |

Length |

Hole Diameter |

Dimension |

|

|

(mm) |

(mm) |

(mm) |

(mm) |

(mm) |

(mm × mm × mm) |

|

|

R25 |

38 |

150 |

35 |

35, 41 |

30 |

120 × 120 × 6, 150 × 150 × 8, |

|

150 × 150 × 10, 150 × 150 × 8, |

||||||

|

R32 |

42 |

145, 160, 190 |

46 |

45, 65 |

35 |

150 × 150 × 10, 200 × 200 × 8, |

|

R38 |

51 |

180, 220 |

50 |

50, 60 |

35, 40 |

200 × 200 × 10, 200 × 200 × 12, |

|

R51 |

64 |

140, 220 |

75 |

70 |

60 |

200 × 200 × 12, 200 × 200 × 30, |

|

T76 |

97 |

220 |

100 |

80 |

80 |

250 × 250 × 40, 250 × 250 × 60 |

Self-drilling hollow bar anchor system is the most common used system for rock mass stabilization, especially in tunneling, underground mining and ground engineering industry. It is mainly used for the supporting engineering in the loose and broken rock stratal with difficult to drilling hole. It provides the optimal solution for soil nailing, lock bolting, micro-piling.

Self-drilling hollow bar anchor system fulfills current and increasing demands of the tunneling, mining industry and ground engineering for safer and faster production. The system provides advantages for all areas of its applications, where boreholes would require the time consuming drilling with casing systems in unconsolidated or cohesive soil.

Features and Advantages

Particularly suitable for difficult ground conditions.

An efficient installation since drilling, placing and grouting can be performed in a single operation, saving both time and money.

Self-drilling system eliminates the requirement for a cased borehole in collapsing soils.

Fast, single-step anchoring system with simple equipment able to work with standard track drill (top hammer) or hand-held drilling equipment, eliminating the need for larger casing rigs.

Installation with simultaneous drilling and grouting possible, and post grouting system is simple.

Continuously drilling and grouting under high pressure causes the grout to permeate into looser soils and creates a bulb-effect for increased bond capacity.

Easy installation in all directions, also upwards, and similar installation methods for all ground conditions.

Suitable for working in limited space, height and in areas of difficult access.

Galvanizing for enhanced corrosion protection is available if necessary.

Multiple ranges of drill bits suitable for different ground conditions.

Continuously threaded bar pattern can be cut and coupled anywhere along its length to achieve all lengths.

Applications in Tunneling & Ground Engineering:

Radial bolting

Tunnel repair and refurbishment

Cliff and Slope stabilization and reinforcement

Fore poling

Micro injection pile

Face stabilization

Temporary support anchor

Portal preparation

Soil nailing

Rocknetting retention

Our Company

Shandong Jute Steel Pipe company established in 2001,now,We are equipped with advanced production equipment,such as hot rolling production line,punching lines,fine rolling production lines and cold drawing production lines.Our company specializes in the production of various seamless steel pipes. Our products include common seamless steel pipes,fine pull pipes,fine rolled pipes,alloy steel pipes,special pipes,sheet steel,Steel pipe deep processing,etc. Our company invites a group of excellent technical experts and management personnel in domestic steel pipe industry to improve the technical levels of our products.

Contact information

Shandong Jute Steel Pipe Co.,Ltd.

Contacts: Mr. Ji

WhatsApp: +86 18865211873

WeChat: +86 18865211873

E-mail: jutesteelpipe@gmail.com

E-mail: juteguanye@aliyun.com